The smart Trick of Best Dust Extractors That Nobody is Discussing

Table of ContentsWhat Does Best Dust Extractors Do?The Ultimate Guide To Best Dust ExtractorsBest Dust Extractors for DummiesWhat Does Best Dust Extractors Mean?The Only Guide to Best Dust ExtractorsGetting The Best Dust Extractors To Work

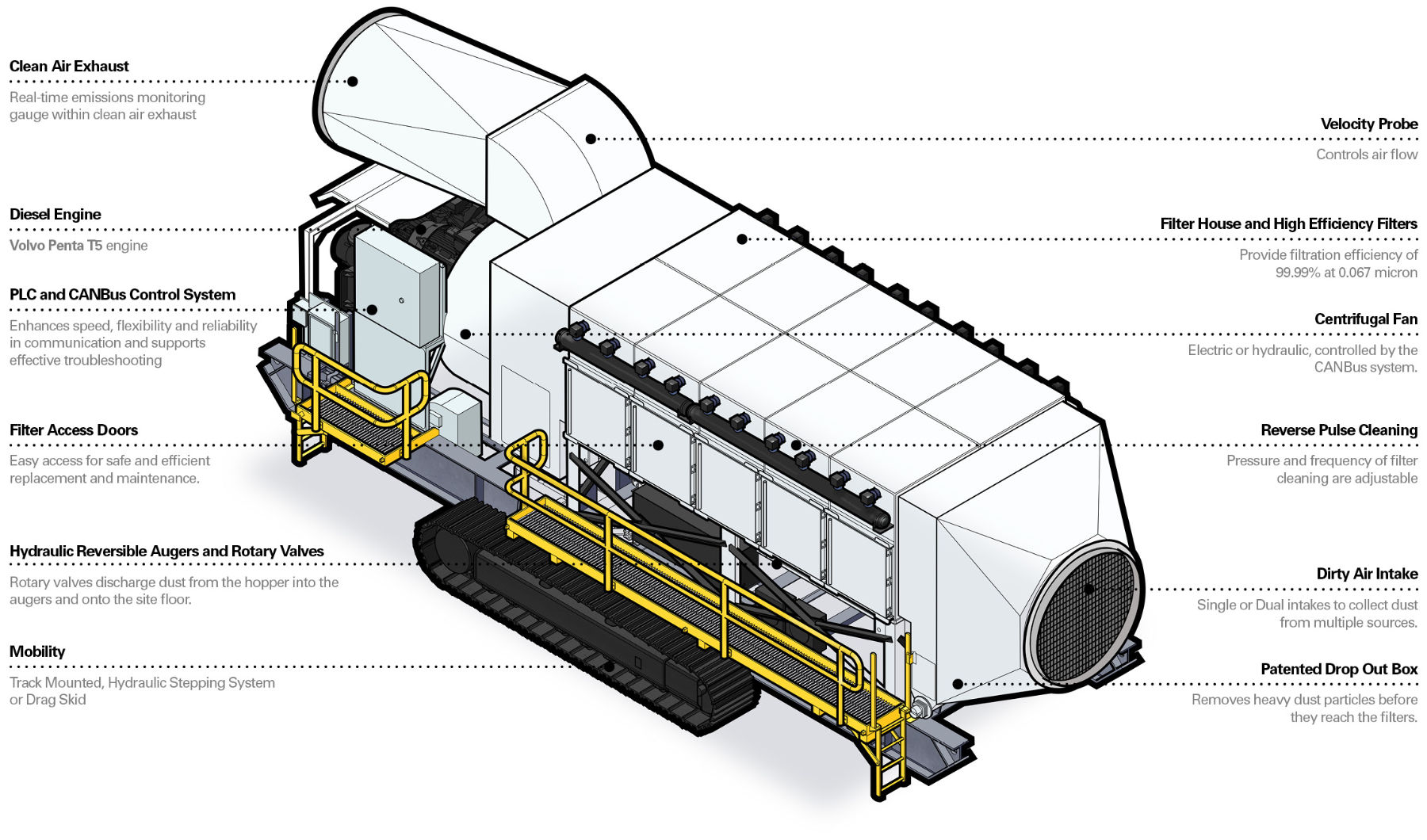

Dirt control systems for mining procedures must hold up against heavy use but be adaptable sufficient to adjust to a wide range of conditions. The nature of mining dust requires very durable as well as reliable equipment since mining dust can be harsh and rough as well as extremely fine. The various kinds of mining identify the sort of dirt collection system.

The dust bits from fiberglass have a tendency to stick despite if the process is grinding, reducing, or some other form of shaping. To fulfill the standards of OSHA and NFPA, fiberglass dust collection systems have to have fire and surge protection components. The air high quality for fiberglass dirt control systems is closely monitored due to the wellness threats.

Dust collection systems for this type of procedure need to be especially developed to fit the type of layer being applied. The function of the system is to control and also lessen overspray and dirt.

Though it would certainly appear likely to boost air movement and also activity, this sort of solution might be ineffective and also waste energy. The layout of the cubicle relies on the force of the air getting in the cell or booth. For a lot of systems, it is very important to have a slight vacuum cleaner in the cubicle to avoid possible favorable stress (Best Dust Extractors).

The Best Guide To Best Dust Extractors

One more approach is merely positioning the makeup air link on the top of the cubicle. No matter of the design, it is necessary for the cleaning of the air to have cross air flow. A lot like a cleanroom, air movement in a thermal spray cubicle can be either horizontal or downward, though the downward design is best for dirt collection systems.

When producers choose a dust control system, they are suggested by producers concerning the kind of system that would best fit their needs given that acquiring as well as installing a dust control system is a significant investment. Particle issue can be found in a wide array of types, from silicon dust to timber chips and also sawdust.

Carbon Penalty carbon dirt can be discovered in different manufacturing processes and also is removed using polyester filters. Best Dust Extractors. Molybdenum Molybdenum dirt is created during the mining procedure as well as is removed using a baghouse system. Seasoning Dirt Seasoning dust is developed by the manufacturing of any type of type of flavor, from cinnamon to sesame seeds.

Sawdust This is the most usual material removed by dirt collection systems. Cartridge or baghouse techniques can be made use of, with baghouse being the most effective.

The Basic Principles Of Best Dust Extractors

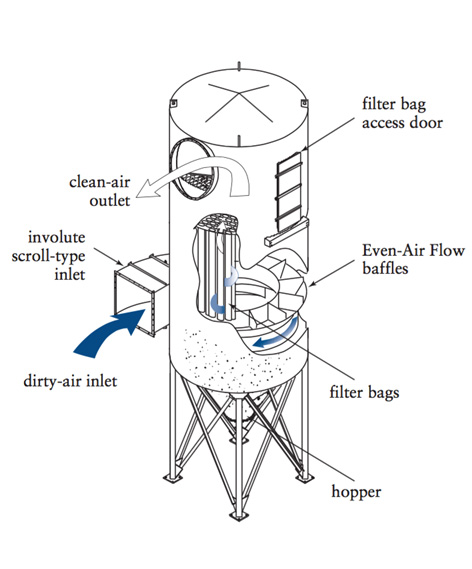

Textile filter bags in a cartridge system are the most efficient technique for accumulating dirt. Dust collection systems are covered to include the dirt as well as tidy the air.

Plastic Dust High-Density Polyethylene (HDPE) dirt is generated in the manufacturing of plastic panels when they are designed and based on a side leaner, mill, or miter saw. Paper Dirt One of the much more typical kinds of dust is paper dust, the negative effects of the manufacturing of numerous sorts of paper.

With the introduction of dirt collection systems, workers are more secure and extra protected. Pulse jet systems are used to keep the filters of the dust collection system particulate-free.

Rice Dust Rice dirt has very fine and also minute bits that build up throughout the manufacturing of rice-based products. A dirt collection system is required for the security as well as safety and security of workers.

Rumored Buzz on Best Dust Extractors

Cosmetic Powders The production and also manufacture of aesthetic products create a large amount of dirt that conveniently moves to all areas of the production facility and also makes the air harmful. To control the problem, producers mount dirt collection systems such as baghouse and cartridge kinds. Shot Blasting Dust collection systems for shot blasting and site here also sandblasting are needed to page gather the blasting product, debris, and also dirt.

The material from the process can harm tools. The dust collection system aids by getting rid of blast product. Rock Dust Rock dust collection systems are used at quarries and mining procedures. They are durable devices made to operate in harsh as well as dangerous problems. Their main function is to control ambient dirt that belongs of the mining procedure such that it does not spread from the location of the procedure.

In the best problems, gathered dust can become unsafe, dangerous, as well as explosive. Any type of build-up of dirt, in the existence of the right ignition source, can produce an explosion. In certain situations, dust can self-ignite without needing a firing up agent, such as when fixed accumulates as the bits scrub together.

A preliminary understanding of the problems that develop eruptive dust offers business with the knowledge to avoid such conditions and be proactive in their action. Given that explosions can possibly hurt workers, the Workplace for Security and also Health Management (OSHA) has actually developed a collection of standards to direct companies in guaranteeing worker safety.

A Biased View of Best Dust Extractors

7. Other activities that can assist in making a dust-filled setting safe are: Surge Vents Surge vents can be mounted on a dirt collector system to offer alternate ways for flames or broadening gasses to run away. They soothe the internal pressure and tear when the pressure degree is surpassed. Explosion Latches Surge latches operate under the same concept as surge vents.

Preventative Maintenance Plan Of the various techniques to deal with possibly explosive issues, proper care of the residential property and maintaining areas clean are the easiest and most logical approaches for staying clear of eruptive and combustible conditions. Such plans are normally created in sychronisation with safety workers and also authorities that have territory.

They trap exhaust and lower the temperature level of warmed fragments before they enter a dust-collecting gadget. They channel triggers my site and embers away from the dust collection system, where the triggers are cooled down to stop explosions and fire.

Additionally, there are requirements regarding the removal of flammable dust particles. The main focus of OSHA requirements is a specification of the preventative measures being taken by a company to shield the health and wellness of its staff members. No matter the absence of dust collection criteria, OSHA does favor that producers have a dust collection system to manage dirt buildup.

Best Dust Extractors Things To Know Before You Buy

Each sector has a different variety of contaminants as well as damaging particles to be gotten rid of. With the growing concern for the setting, dust collection systems have ended up being vital to many industrial and production operations.